PRODUCT DEVELOPMENT STORY 01

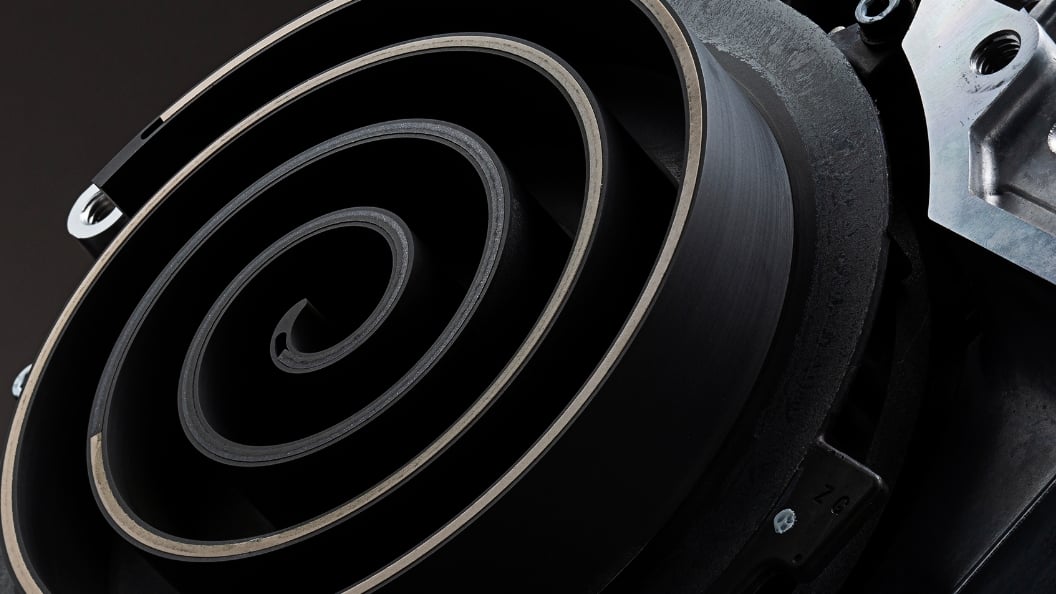

Scroll Compressor

It was ANEST IWATA that first introduced the world’s first commercial oil-free scroll compressor. Its birth dates back to 1991.

01.BENEFITProvides Clean Air of the Highest Quality

Our scroll processors provide safe and reliable oil-free air, made possible with the proven technology we developed for the first time in the world. Certified as Class 0 by international machinery standards, they boast rock-solid safety and a level of quietness that defies commonly held preconceptions about compressors.

02.HISTORYBecoming the World’s First

Aiming to Promote the Use of Oil-Free Compressors

Oil-lubricated compressors were the norm in the 1980s, and our main products consisted of oil-lubricated piston compressors as well. With our continued attempts at refining our technology, we succeeded in developing an oil-free piston compressor, but as with other competing products, it required maintenance around the piston ring every 2,000 to 3,000 hours, which presented an obstacle in popularizing oil-free compressors. We began developing oil-free scroll compressors in order to overcome these issues.

Breakthrough

There was no rulebook regarding the development of an oil-free scroll compressor, since no one had done it before, so our team continued to grope in the dark for clues. The most difficult issue was in creating the rotating motion typical of the scrolls. This was considered difficult to achieve with the oil-free methods that existed at that time, but we came up with the world’s first pin crank mechanism, and succeeded in creating a stable and highly accurate rotating motion. We also managed to add a mechanism that made the clearance of the rotating scroll easily adjustable. If it were not for this feat, we would not have been able to move forward with development; we consider this mechanism to be the greatest invention that made the oil-free version possible.

World’s First Commercialization

Five years had already passed since 1985, surpassing the period originally set aside for development. Although the prospect of commercialization was assured, the development deadline, which had been extended due to the inability to completely eliminate unstable elements relating to quality control, drew near once again, and the company was forced to decide whether or not to proceed with the launching of the product. Extensive discussions were held within the project, and the company finally decided to extend the time allotted for development by one year. The team spent that year meticulously inspecting the issues and eliminating the elements that gave rise to concerns, which allowed them to finally reach the launching stage. Following this, the company introduced the world’s first oil-free scroll compressors, the SLP-22 (2.2 kW) and the SLP-37 (3.7 kW), in March 1991. In the 30 years since then, we remain number one in the world in terms of production and sales of these compressors.

03.MESSAGEMaking a Meaningful Contribution to Our Customers and Society Through Product Development

In order to be the first in the world to develop the oil-free scroll compressor, we staked our company’s survival. And we believe that we were successful in our attempt only because of our determination to achieve it, as well as the desire to serve our customers and society with the product we made. In fact, we have never felt the need to use our brand name for our scroll compressors during the 30 years since their launch. This is because we strongly believe that “scroll compressors will become synonymous with ANEST IWATA.” In order to make this belief a reality, we hope to use this first-in-the-world technology to discover new endeavors that fuel our determination, and in doing so, make an even more meaningful contribution to our customers and society as a whole, while always remembering the support that kept us going these past 30 years.