BRAND STORY 01

1926-1930

Iwata Seisakusho Is Born.

From the humble beginnings of a small workshop

unfolds a remarkable hundred-year history

The four Iwata brothers (from left to right: Harukichi, Sukezo, Hatsutaro, and Fukutaro)

Two Brothers Start Their Own Business: "It's Now or Never!"

Hatsutaro Iwata becomes an apprentice at an electric firm to support his family

Our company started out on May 1, 1926, as a small workshop in a rented corner of a factory in the town of Toyosawa, Shibuya Ward, equipped with only two used lathes. The founders were two brothers: Hatsutaro Iwata and Sukezo Iwata. The older brother, Hatsutaro, was born in August 1901. The younger brother, Sukezo, who continued to support his older brother throughout his life, was born in May 1905.

When the brothers were little, the Iwata family was so poor that they often did not know where their next meal was going to come from. Their father, Kosaburo, was a self-centered, haughty man with craftsmanlike pride, who spent all his wages on gambling and alcohol, never caring about his family. Their mother, Umeno, had a side job of dressmaking and borrowed money from relatives in order to keep the children fed. The boys started elementary school a few years apart, but the family was too poor to buy pencils or notebooks, or even to pay the monthly school fee of 10 sen (or 0.1 yen). To supplement the family income, the two brothers worked for one of their uncles every day, making parts for tea strainers.

In the hopes of supporting his struggling family, Hatsutaro left elementary school when he was in fourth grade and joined a small local factory. He initially found work as an apprentice at an electric firm, where he processed sockets, but disheartened by the tedious work and the lack of future prospects, he quit after two years. Hatsutaro then became a lathe apprentice at Sanko Seisakusho, a company specializing in the manufacturing of steel pipe joints, spinning machinery, and printers among other things, where he earned 17 sen a day. At the age of 21, his apprenticeship ended.

Having honed his skills as a craftsman, Hatsutaro establishes "Iwata Seisakusho" with Sukezo

It was common at the time for craftsmen who had served their apprenticeships to find another job to refine their skills. However, Hatsutaro's skills and character had come to be highly regarded by the people at the company, and they asked him to stay. They offered to pay him a monthly salary of 60 yen, and entrusted him with the instruction and supervision of the other employees as well as external business negotiations. The younger brother, Sukezo, was able to graduate from elementary school, thanks in no small part to the financial support from his big brother. Since Sukezo excelled academically, his teacher urged him to continue his studies, but he chose to work at his uncle's factory to help support his family. A year later, he resigned from the factory and joined his beloved brother at Sanko Seisakusho. At the time, the wages of the two brothers combined was just about enough for the family to make ends meet.

However, the brothers both agreed, "We shouldn't be content working for other people forever. Let's promise each other we'll go independent in the near future." In addition to their monthly salaries, the two young men saved up what little money they earned from their side job of making tea strainers, and bought the necessary tools and equipment. Later, Hatsutaro left Sanko Seisakusho and went through a number of different jobs, working at various places such as a factory making woodworking machinery and an iron factory. He continued to improve his skills, preparing for the time when they would go independent, telling himself, "Keep yourself prepared for luck." In May 1926, Hatsutaro tried to borrow 450 yen out of the 500 yen needed to set up his own business from an uncle who was the head of the Japan National Railways factory in Omiya, Saitama Prefecture. The uncle turned down his request, saying, "We are going through a recession, and this is not a good time. Wait a little longer." But nothing could stop Hatsutaro's aspiration of starting his own business. Thinking that it was "now or never," he borrowed money from another uncle who ran a tofu shop, and founded Iwata Seisakusho in the town of Toyosawa, Shibuya Ward.

The Brothers Succeed in Developing the First Japan-Made Spray Gun

The brothers are asked to manufacture a spray gun to popularize lacquer coating

Iwata Seisakusho initially started out doing subcontracted work, manufacturing parts for typewriters, bench drills, and radios, but the business was not going as well as they had hoped. At the time, Sukezo was working at Mizushima Shokai, a company that sold foreign cars and offered limousine taxi services, as well as after-sales and repair services for the cars they sold, and his salary kept Hatsutaro's business going. Two months after Hatsutaro founded Iwata Seisakusho, Sukezo left Mizushima Shokai and joined his brother. The brothers had decided to go for broke. One month after Sukezo quit, he was summoned from Mizushima Shokai. Sukezo went to see the president of Mizushima Shokai, who took out a brand new device made of brass and asked, "Can you make something like this?" It was the latest spray gun model made by the American firm Binks Corporation. When President Mizushima had visited the US to buy cars, lacquer coating, which was then the most advanced technology of its time, had caught his attention, and he had signed a contract to import Binks's coating equipment in addition to materials such as lacquers and thinners. However, the products made by Binks were extremely expensive and presented an obstacle in the quest to popularize lacquer coating. That was when he hit upon the idea of having cheaper spray guns produced in Japan.

After countless attempts, the first spray gun comes into being, made possible by a craftsman's persistence

Blithely thinking that the spray gun would be easy to make, Sukezo made a deal on the spot to produce a dozen spray guns at 50 yen apiece, agreeing to the condition that payment would be made after delivery. Hatsutaro and Sukezo studied the sample spray gun from every angle, completed the ordered spray guns in three months, and delivered them to Mizushima Shokai. But, when Sukezo went to collect the payment several days later, he was stunned to be told that they could not pay him since the spray guns were all defective. Mizushima Shokai cited several reasons, such as insufficient spraying power, uneven spray patterns, poor suction, and a heavy trigger. The brothers reworked the spray guns numerous times and brought them back, but the company refused to accept them every time. It was only natural, considering that not only did the brothers know nothing about the basic principles of producing a vacuum to suck paint, but they also lacked the financial means to purchase a compressor with which to test their products. They asked President Mizushima to let them use the company's compressor, but the president did not allow them even to touch it, saying, "We'll do the testing for you if necessary." The brothers had to complete the spray guns, however, as otherwise they would not be paid and would not be able to pay for the materials either. After countless retries, a few of their spray guns finally passed the test. It had been about six months since the brothers received the order, and their funds were nearly depleted. It was an achievement that only the determination and persistence of craftsmen could accomplish. Their spray gun, the first ever created in Japan, had a big head and a rugged grip, but it was capable of producing both flat and round spray patterns and atomized paint well.

Manufacturing Equipment for Lacquer Coating and Selling It Across the Country

The brothers develop sales channels on their own, and with the spread of lacquer coating, orders come in from all over the country

As Iwata Seisakusho began to receive orders from Mizushima Shokai, it became financially stable. With the start of the Showa era (1926-1989), orders poured in due to the popularization of lacquer coating. The brothers also began to receive orders for air transformers (air-purifying pressure regulators) used to ensure a stable supply of air pressure. The brothers decided to turn Iwata Seisakusho into a specialized manufacturer of coating equipment, and relocated their operations to a small factory in Toyowake, Shibuya Ward, in February 1927. However, at the end of that same year, Iwata Seisakusho was involved in a dispute with Mizushima Shokai over payment issues, and ceased to do business with them. The loss of a major client was a massive blow financially, but considering that Mizushima Shokai would go bankrupt later on due to the recession and embezzlement by the head clerk, this may have actually been a blessing in disguise.

Iwata Seisakusho had to find its sales channels on its own. The brothers set their eyes on the wholesalers and retailers of paint. Sukezo Iwata, who took full charge of sales operations at the time, visited paint retailers in Tokyo one by one on bicycle, showing them how to use a spray gun and asking them to stock it. As Iwata Seisakusho's products began to sell at these retailers, the number of dealers grew in tandem. On his way back from trips to source raw materials, Sukezo also dropped into the paint shops in Itabashi and even Kawaguchi in Saitama Prefecture, and the number of retailers rose further. However, it was through advertisements in newspapers and magazines specializing in paint, coating, and automobiles that Iwata Seisakusho was able to boost sales nationwide. In part because lacquer coating was becoming more widespread, orders arrived from all over the country.

Iwata Seisakusho had to find its sales channels on its own. The brothers set their eyes on the wholesalers and retailers of paint. Sukezo Iwata, who took full charge of sales operations at the time, visited paint retailers in Tokyo one by one on bicycle, showing them how to use a spray gun and asking them to stock it. As Iwata Seisakusho's products began to sell at these retailers, the number of dealers grew in tandem. On his way back from trips to source raw materials, Sukezo also dropped into the paint shops in Itabashi and even Kawaguchi in Saitama Prefecture, and the number of retailers rose further. However, it was through advertisements in newspapers and magazines specializing in paint, coating, and automobiles that Iwata Seisakusho was able to boost sales nationwide. In part because lacquer coating was becoming more widespread, orders arrived from all over the country.

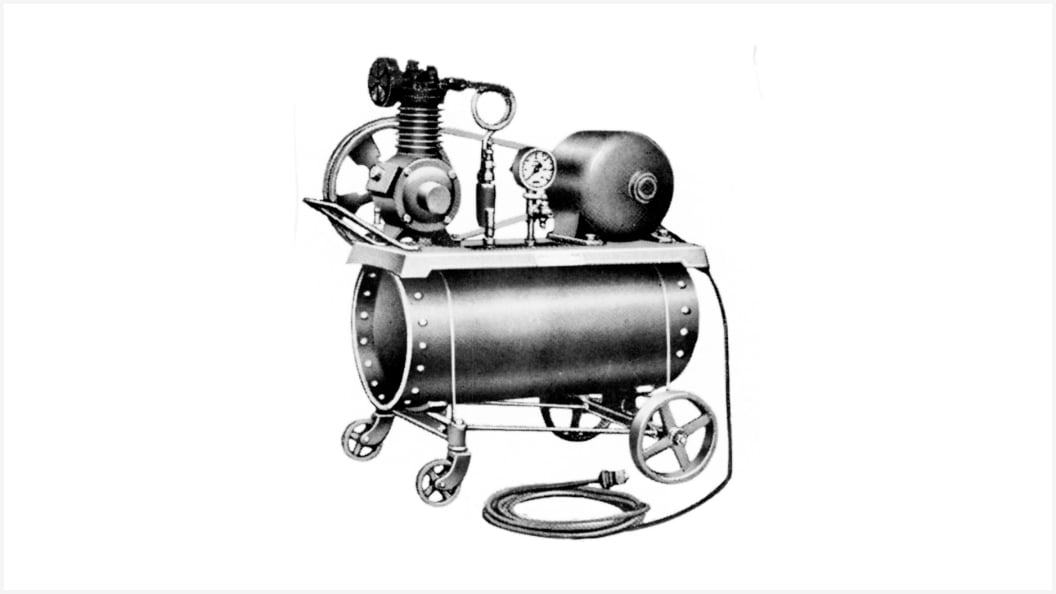

Manufacturing inexpensive spray guns and compressors to sell across the country

In line with the increasing demand for spray guns, Iwata Seisakusho poured its energy into developing new products. What they first focused on was developing an entry-level model of their spray gun. Based on his more than a year of experience struggling with spray guns, Hatsutaro made the head of the spray gun simpler and succeeded in cutting the price almost in half. Also, the company expanded its lineup to include various pieces of equipment needed for lacquer coating, starting domestic production of Curtiss-type air compressors developed by the eponymous American company, and manufacturing air transformers. Successfully riding the wave of widespread lacquer coating, sales at Iwata Seisakusho rose sharply, and the company was able to repay all the money it had borrowed at the time of its founding. Moreover, it even had money left over to expand its production capacity.

This was how, in 1930, the company came to purchase land of about 120 tsubo (1 tsubo being roughly equal to 3.3 square meters) in Mukoyama, Shibuya Ward, in front of Ebisu Station, and build a factory and store there. The brothers took this opportunity to rename the company "Iwata Spray Coating Equipment Seisakusho." In 1932, they won a huge contract with Mitsubishi Corporation to supply 12 coating equipment units including compressors. As their spray guns and compressors came to be renowned for their performance, the company acquired major new clients, such as gasoline meter manufacturers and car maintenance equipment dealers, and its network of retailers expanded across the country.