BRAND STORY 03

1961-1985

Surviving the Recession by Streamlining Management and Improving Productivity.

Laying the Foundation for Overseas Expansion, and Developing the World’s First Painting Robot

Painting Robot AR-62 (hydraulic type)

Pursuing the Twin Goals of Streamlining and Reinforcement in the Midst of a Recession

The company consolidates and integrates two production facilities to streamline production, and builds a General Technology Center to enable advanced research and development.

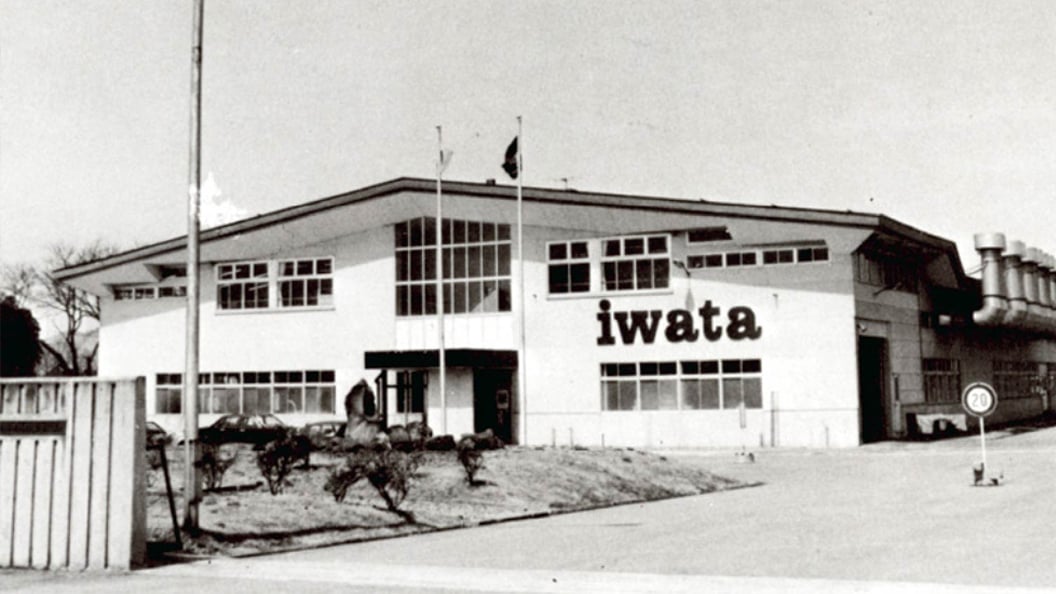

At the beginning of 1965, Japan was hit by a recession, which would later be called the “Showa 40 recession” (referring to the 40th year of Showa; alternatively referred to as “the structural recession”). Many companies in our industry went bankrupt because of the slumping economy. Iwata Air Compressor Manufacturing was also forced to tighten control over its finances and further streamline its operations. The most pressing issue on the agenda was the integration of production facilities dispersed between two factories—the No. 1 and No. 2 Factories in Tsunashima. By integrating all the facilities into the No. 2 Factory, the company hoped to reduce management costs and inventory, while becoming more environmentally friendly. The construction work for the integration started in August 1965, and the company started moving the facilities from the No. 1 Factory in February of the following year, finishing in November of the same year. At the site of the new factory, a separate building was constructed for each product category (spray guns, air compressors, coating systems, etc.), boosting productivity significantly. Also, the company built a General Technology Center, in order to provide an environment that enables more advanced research and development.

The company establishes the Osaka Branch and the Kyushu Sales Office to reinforce sales activities and after-sales services.

In order to pursue sales more aggressively, Iwata Air Compressor Manufacturing established the Osaka Branch (October 1966) and the Kyushu Sales Office (April 1968). Both were the result of absorbing two firms in the respective regions that the company had established jointly with Umei Industry Co., Ltd., Iwata Coating Equipment Corporation (Osaka City) and Kyushu Iwata Coating Equipment Corporation (Kita-Kyushu City). The Kyushu Sales Office was moved to Fukuoka City in August of the same year, and renamed the Fukuoka Sales Office. Setting up these two branches brought significant gains, not only by cutting out middlemen, but also boosting sales and improving after-sales services.

Responding to the Rising Demand for Medium-Sized Air Compressors

The company starts development of medium-sized compressors and sets its eyes on air coolers based on thorough market research.

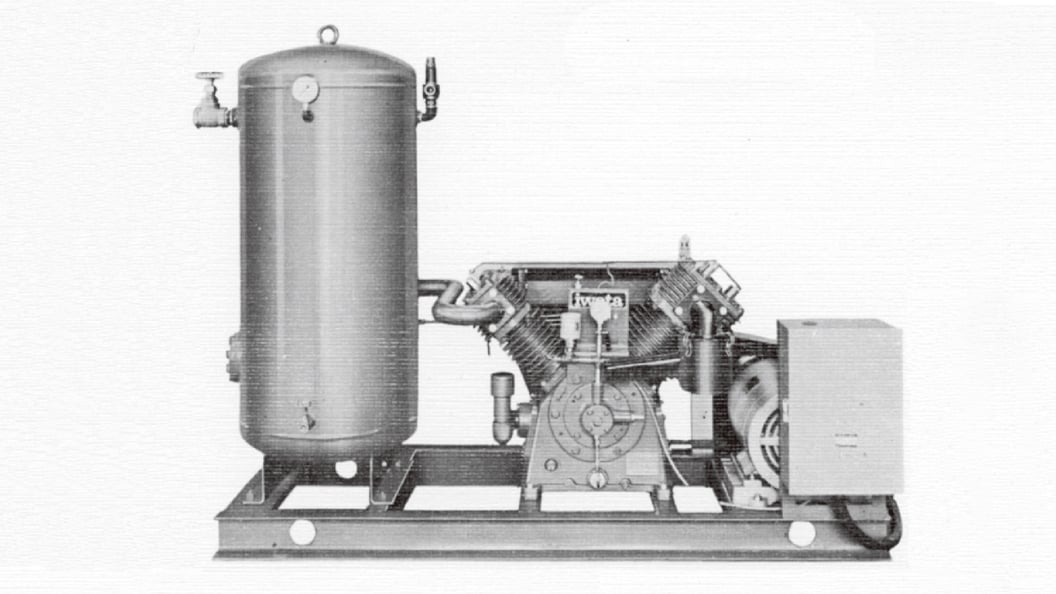

As industrialization progressed, the trend of the demand for air compressors began to change in the mid-1960s. While small-sized air compressors had been the mainstream up until then, the demand for medium-sized air compressors with larger capacity was growing. Iwata Air Compressor Manufacturing started developing medium-sized air compressors around 1965. However, the medium-sized air compressor market was fiercely competitive, with major first-mover manufacturers jockeying for position. This was why the company devised a development strategy centered on air coolers, which intensive market research, including for overseas markets, seemed to indicate as a good candidate. While product development was going forward, the company purchased a piece of land next to the Yokohama Factory, and completed the construction of a factory dedicated to medium-sized air compressors in 1968. This factory started full-scale operation in the fall of 1969, launching mass production.

Establishing a Subsidiary in the Netherlands and Making Forays into the European Market

With the Wider spray guns garnering favorable reviews in Europe, the company aims to establish a sales network there.

By the mid-1960s, Iwata Air Compressor Manufacturing was exporting its products to 20 countries around the world. In particular, its spray guns were well received in Taiwan, and its small-sized air compressors were earning rave reviews in Thailand. However, with the company completely tied up trying to meet the demand of the domestic market, developing overseas markets remained a challenge for the future. At the time, the most attractive market for the company was Europe. In 1965, upon exporting Wider spray guns to European countries such as Finland, Sweden, and Denmark, the company was heartened by the positive feedback. Moreover, the popularity of these spray guns provided a foothold for marketing in Belgium and the Netherlands as well. Based on these circumstances, the company came to the conclusion that it should open a representative office in Europe and establish a sales network.

The company is forced to close down its office in the Netherlands soon afterwards, a valuable experience that would inform future overseas expansion.

In October 1968, the company established a local subsidiary called “Europe Iwata” in The Hague of the Netherlands (Den Haag). Two employees were sent over to this subsidiary to market coating equipment and air compressors. However, after dealership agreements were signed with ten local retailers and efforts to market the products began, problems emerged that had not been evident during the market research. As in Japan, coating jobs were unpopular because they were considered difficult, dirty, and dangerous (referred to as the “3K problem” in Japan). The workers employed in these jobs tended to be unskilled and uneducated, and coating equipment was handled poorly. Unfortunately, the company was taken up with the development of medium-sized air compressors at this time, which consequently derailed the effort to develop products focused on the needs of the European market, and hampered sales. As a result, in July 1969, Europe Iwata was closed down. However, this foray into Europe gave the company a deep understanding of the markets there, and allowed it to acquire local dealers. This experience would later form the foundation for the company’s overseas expansion in the future. Twenty years later, the experience would pay off in a big way.

Establishing Production Bases Nationwide in Anticipation of an Increase in Demand

The company builds a new coating equipment factory in Akita Prefecture, later to become the central site for spray gun production.

As the land surrounding the Yokohama Factory was designated as an Urbanization Control Area in 1969, Iwata Air Compressor Manufacturing began a nationwide search to find a suitable site on which to build a factory dedicated to producing coating equipment and air compressors, apart from the one in Yokohama, in anticipation of a future surge in demand. From several candidate sites, the company chose the premises of Fujiki Junior High School, located in Omagari City (the present Daisen City) of Akita Prefecture, that was scheduled to be closed down. The company decided to build a factory dedicated to coating equipment there. In October 1972, the new factory was established as the Tohoku Iwata Coating Equipment Co., Ltd. (later renamed the Akita Iwata Coating Equipment Co., Ltd., and presently the Akita Factory under the aegis of the Coating Division) with a capital of 50 million yen. The factory has continued to grow steadily ever since, not only serving as the central site of our spray gun production, but also functioning as the technological backbone for our spray gun production overseas.

A New Management Team Overcomes a Direct Hit by the Oil Crisis

Kazuya Iwata, then managing director, is appointed as the new president, and the company implements organizational reform in response to the worsening market conditions for coating equipment.

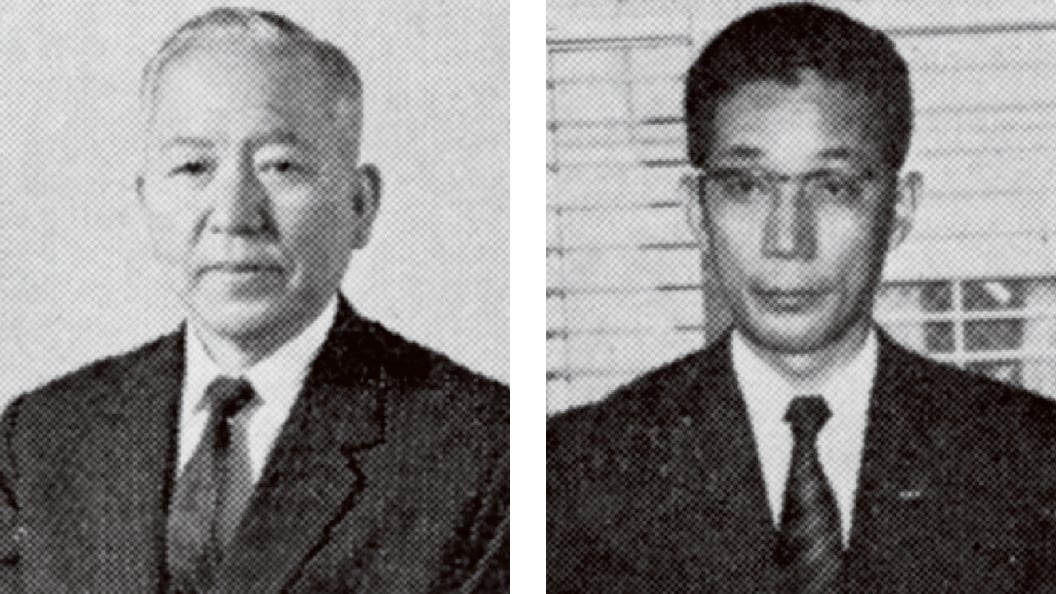

Right: Kazuya Iwata, the newly appointed president (41 years old at the time)

On May 29, 1973, Iwata Air Compressor Manufacturing went through a management shakeup, installing a new president in the process. Sukezo Iwata, who had been at the helm of the company since succeeding the first president, Hatsutaro Iwata, in 1965, stepped down to serve as chairman, and Kazuya Iwata, then the senior managing director, was appointed as the new president. As the new president took office, the company announced its first-ever three-year business plan. However, the new management team faced daunting conditions. In fact, the team found the company fighting for its survival in stormy seas. In October 1973, the first oil crisis hit Japan, whose economy was overheating due to the so-called “Reconstruction of the Japanese Archipelago” plan. The coating equipment market shrank substantially, and the company experienced rampant inflation. Its drastic organizational reform was intended to respond to such changes.

The company manages to survive the recession—which leaves a trail of bankruptcies in its wake—by instituting drastic changes, such as shifting to a divisional system capable of responding quickly to the market needs for each product.

The company first placed the R&D and production departments at the core of its organizational structure, and shifted to a divisional system comprising of the coating equipment division and the air compressor division, thus allowing it to respond quickly to the market needs for each of its products. Secondly, the company spun off the production engineering department as an independent unit, so that it could handle all the products made by the company. From around 1973, market conditions worsened, and the country suddenly found its economy stalling after many years of dizzyingly rapid growth. Difficult times loomed ahead. In order to kick-start its faltering business performance, the company implemented a series of measures, including relocating surplus personnel to support sales activities and laying off employees. The company could no longer afford to keep up appearances. It was through these desperate measures of blood, sweat, and tears that the company survived the nightmarish period from 1975 to 1976, during which company after company went bankrupt.

Expanding Production Capacity in Preparation for the Future

The company builds a factory dedicated to small-sized air compressors in Fukushima Prefecture, equipped with the latest automated production lines and state-of-the-art facilities.

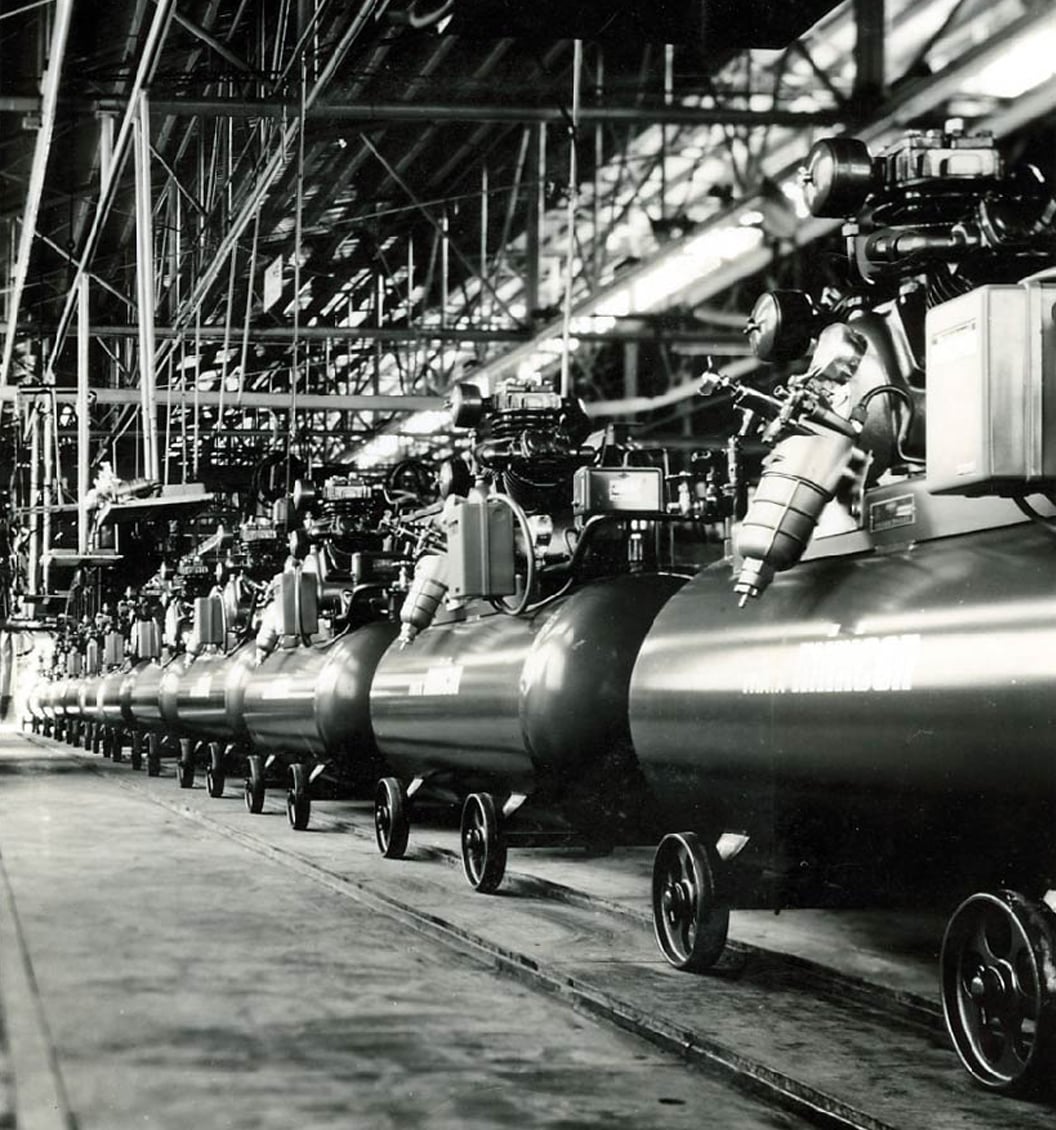

While making an all-out effort to survive the recession, Iwata Air Compressor Manufacturing was also speeding up the establishment of a three-base domestic production system to prepare for the future need to increase production. In particular, relocating the air compressor body processing and assembly departments that occupied much of the floor space of the Yokohama Factory was seen as the key to a future increase in production. Among the candidate sites, one met all the conditions—availability of industrial water, electric power, and a labor force, plus convenient logistics—which was the town of Yabuki in Nishi-Shirakawa County, Fukushima Prefecture. In September 1975, the Fukushima Iwata Coating Equipment Co., Ltd. (the present Fukushima Factory under the aegis of the Air Energy Division) was founded with a capital of 80 million yen. In order to win the increasingly cutthroat price wars, the Fukushima Factory, where small-sized air compressors were manufactured, was equipped with NC lathes, machining centers, and other state-of-the-art facilities, including the latest automated production lines. The factory received an additional infusion of capital of 300 million yen in 1978, and the second phase of construction began in April 1981. With the completion of production facilities for air tanks, coating, and assembly lines, the Fukushima Factory started operations in October as a bona fide integrated small-sized air compressor production facility. With a production capacity of 3,000 units per month, the factory first produced the N series of small-sized air compressors, followed by the P series.

Development of Japan’s First and the World’s First Painting Robots, One After Another

The company develops painting robots in partnership with Mitsubishi Heavy Industries, in response to the automation of factories and coating work.

One problem that continued to plague the Japanese industrial sector at the time was the shortage of human resources resulting from an aversion to so-called “3K” jobs. Coating jobs were no exception, and so there was an urgent need for factory automation (FA). To address this situation, Iwata Air Compressor Manufacturing partnered with Mitsubishi Heavy Industries, Ltd. to jointly develop the first ever painting robot made in Japan, the AR-62. This robot was introduced to the market in August 1975, and it was highly praised not just in Japan but overseas as well. In 1980, the company launched the AR-63, the world’s first painting robot equipped with a data processor with a microcomputer. This was followed by the MRP series of painting robots, released in 1982, which was the first in the world to be controlled by microcomputers. In 1985, the company unveiled the MRP-400 series, the world’s first eletric direct teaching robots. The painting robots gained high acclaim, because, combined with equipment such as conveyors and driers, they offered a comprehensive solution to customers in need of automated coating. Since then, these robots have continued to be improved as the foundation for the development and expansion of our coating systems business, and are made to this day.